Understanding and Automating Pharmaceutical Water Quality Monitoring with TOC Analyzers

Join us for a webinar as we discuss the use of total organic carbon (TOC) analysis as a powerful tool for pharmaceutical water quality monitoring. Our expert, Dr. Pravin Konde, will bring us through the tips and tricks on how on-line TOC monitoring can improve accuracy, reduce labour costs, and ensure regulatory compliance with EU GMP Annex 1 requirements.

In addition, we will also introduce Shimadzu's TOC-1000e, a compact yet powerful analyzer that automates pharmaceutical water quality monitoring to boost your productivity at work. Discover the workflow solution with us, from intuitive usage to learning the advanced data management system and fast maintenance procedure to optimize water treatment processes.

Sign up for the webinar below, or read on for bonus resources!

Introduction to Total Organic Carbon (TOC)

TOC analyzers measure the total amount of carbon contained in organic matter in water (Total Organic Carbon). The amount of organic matter in water is an index of water quality.

TOC analyzers are used in the following fields and industries. They contribute to protecting the environment and the water we drink.

| Fields and Industries | Typical Samples Measured |

|---|---|

| Water and sewerage | Drinking water and purified water |

| Environment | Oceans, rivers, and soil |

| Pharmaceuticals | High-purity water and washing water |

| Semiconductors | Ultrapure water for cleaning |

| Manufacturing | Industrial effluents, cleaning solutions, and plating solutions |

Analysis Methods With TOC Analyzers

The primary difference between TOC analyzers is the oxidation technique. Most TOC analyzers convert all carbon to carbon dioxide and measure the CO2 with a CO2 specific non-dispersive infrared (NDIR) detector. NDIR detection requires CO2 be swept by a carrier gas through the detector. It is more specific than membrane conductivity. Membrane conductivity diffuses CO2 through a membrane into an absorber solution. Any change in conductivity of the absorber solution measures CO2.

Catalytic combustion oxidizes organic compounds to CO2 and H2O at lower temperatures.

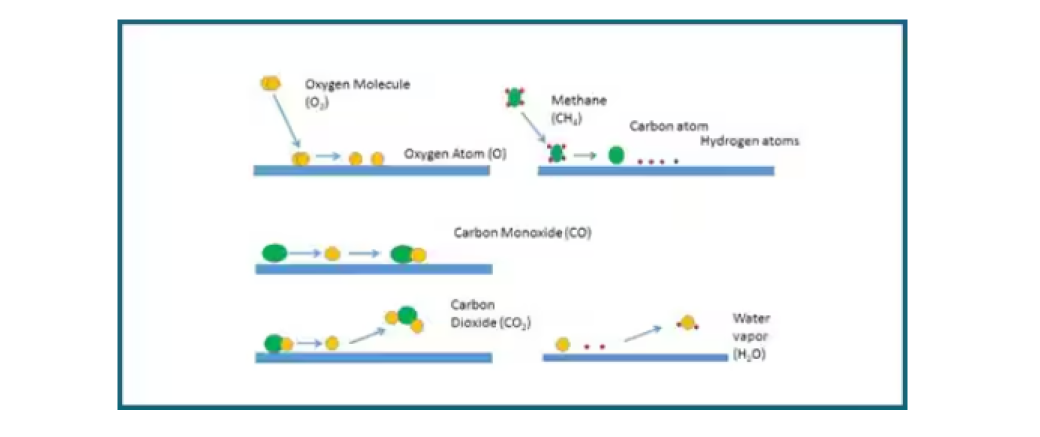

The carrier gas containing oxygen passes over a hot metal catalyst. The oxygen molecules split to oxygen atoms that coat the surface of the catalyst. Injected sample, or fuel, splits into atoms on the surface of the catalyst. In Figure 1, the fuel is methane. A carbon from the methane collides with an oxygen atom to form carbon monoxide. Because of its affinity for the catalyst the CO molecule stays put until it collides with another oxygen to form CO2. The CO2 flies off into the carrier gas. The hydrogens from the methane also collide with oxygen to form OH- first and then H2O, which also enters the carrier gas. This process continues as the fuel percolates through the catalyst bed.

Once there is no more fuel, the catalyst recoats with oxygen from the carrier gas.

The mode, or mechanism, of collision is different with catalytic oxidation as compared to combustion. In combustion, the collisions occur in the gaseous phase, requiring very high temperatures to induce enough collisions in the shortest time possible. The carrier gas needs to be pure oxygen to ensure adequate collisions. Because the catalytic oxidation takes place on the surface of the catalyst, the temperature is lower. The lower temperature is below the melting point of sodium chloride, decreasing devitrification and increasing the life of the combustion tube.

Wet chemical oxidation TOC reacts an oxidizing chemical with organic compounds to CO2 and H2O.

Under acid conditions, persulfate converts into a sulfate radical, which is a very strong oxidizer. Unlike catalytic combustion, which takes place between a gaseous and solid surface, persulfate reactions take place in solution. Persulfate is not a good oxidizer on its own, but its oxidizing power increases with heat or upon exposure to UV irradiation. The number of collisions between the oxidizer and the sample increases with temperature; unfortunately, the persulfate rapidly decomposes at high heat. In addition, other constituents of the sample matrix, particularly high chloride, react with persulfate, preventing it from oxidizing the carbon.

| Technique | Advantages | Disadvantages |

|---|---|---|

| Catalytic Combustion (HTCC) | - High Efficiency - Lower temperature than HTC - Tolerates high salt |

- Higher detection limit than PO - Memory effects of catalyst - Catalyst poisoning |

| Chemical Oxidation (PO) | - Low detection limits - No memory effects |

- Chloride interferes - Lower oxidation efficiency |

TOC Analyzers Selection Guide

Shimadzu is a leading manufacturer of total organic carbon (TOC) analyzers used in various applications in the environmental and pharmaceutical industries. The Shimadzu TOC analyzers are highly sensitive, which makes them suitable for various applications in the environmental and pharmaceutical industries. Offering a complete TOC instrument lineup, Shimadzu’s TOC analyzer includes the TOC-L series, which uses the combustion catalytic oxidation method to detect organic carbon with the highest level of sensitivity available. The TOC-4200 online water quality analyzer supports a wide range of samples and is easy to operate; while the compact eTOC series on-line TOC analyzer is made ideal for measuring ultra-pure water.

Product Selection Guide helps you to find the most optimal TOC Analyzer from various models. With only 1 minute, you can know which TOC Analyzer best suits your analysis needs.

History of Shimadzu TOC Analyzer: 50 Years of Cutting-Edge Innovation

2022 marks the 50th anniversary since Shimadzu first released a TOC analyzer. Today, Shimadzu TOC analyzers are used in a wide variety of fields ranging from laboratory quality control applications for public water supply management, drinking water management, purified water management in pharmaceutical and other industries, environmental water measurement, and wastewater management, to online measurement applications for water quality or pollutant management of factory effluents into rivers, oceans, etc.

Shimadzu development of TOC analyzers began after Shimadzu established a technical partnership with Hartmann & Braun of West Germany in 1965 and the National Industrial Research Institute of Nagoya asked Shimadzu to develop a TOC analyzer in 1967.

In 1972, Shimadzu developed and released its first TOC analyzer products: the TOC-100 automatic water quality monitoring system for continuous monitoring of water quality and pollutants in public waters based on the Water Pollution Prevention Act and the TOC-10 total organic carbon analyzer for laboratory use.

In 1983, Shimadzu developed the TOC-500, which was the world’s first TOC analyzer with 680°C combustion catalytic oxidation capability. That significantly extended the life of combustion tubes and catalysts and improved ease of maintenance.

In 1989, the TOC-5000 featured a mechanism for automatically injecting samples and expanded the measurement range from the ppm level to the ppb level. That resulted in broader applicability of TOC measurements, including for purified water, and established Shimadzu as the global leader in TOC analyzers.

The TOC-V series released in 2000 featured additional functionality for measuring solid samples, purgeable organic carbon (POC), and total nitrogen (TN), which further expanded the applicability of TOC analyzers. Today, the TOC-L series released in 2011 continues to serve at the forefront of total organic carbon analysis.

Initially, TOC analyzers were mainly used for ensuring the water quality of environmental waters, industrial effluents, and so on, but later, as TOC performance improved, the scope of applications expanded. Now they are also used for quality control of purified and ultrapure water, for ensuring compliance with public drinking water quality standards, for controlling/evaluating pharmaceutical manufacturing processes, and for researching carbon-neutrality. Thus they serve a vital role in a variety of fields important for people and the Earth.

The Importance of Water Quality Control in the Pharmaceutical Industry

In the pharmaceutical industry, it is important to use the purest possible substances and purified equipment and materials in the production of drugs. To meet this standard, legislators have published Pharmacopoeias. These include methods and rules for the manufacture, storage, quality and testing of drugs. For drug manufacturers, complying with the rules and methods of the Pharmacopoeia is mandatory.

TOC determination is also described in the Pharmacopoeia (for instance the European Pharmacopoeia = EP). The sum parameter serves as a measure of contamination by organic compounds. Not only the method itself is described, but also a test to verify the suitability of a TOC analyzer for the analysis.

In addition to ultrapure water required for the manufacture of drugs, water for injections – water that is directly injected into the bloodstream of the human or animal body – is also tested for its TOC content. The Pharmacopoeia actually specifies a maximum TOC limit value for such specific waters.

Many drugs are manufactured in batch mode operation. Prior to the production of the next batch, materials and working equipment must be extensively cleaned. In order to verify that the equipment is free from the ‘previous’ drug batch, the TOC parameter is used for the evaluation of the cleaning process. The TOC not only mirrors the presence of drugs, but also reveals other contaminants such as those from cleaning agents.

With its TOC analyzers, Shimadzu offers systems that are suitable for many different TOC analysis issues in the pharmaceutical industry. In addition to the lowest detection sensitivity, the robust analyzers offer the highest precision and accuracy. Just like the analyzers themselves, the operation and evaluation software complies with all requirements of the FDA and the Pharmacopoeia.

To learn more, register to learn how you can automate pharmaceutical water quality monitoring with Shimadzu’s TOC Analyzers.

Here’s why you should attend:

- Discover how On-Line TOC monitoring of pharmaceutical water system ensures swift contamination detection, ensuring quality water supply

- Gain insights into implementing a TOC monitoring system compliant with regulatory requirements such as USP 643 and 21 CFR Part 11

- Understand the benefits of using Shimadzu TOC-1000e On-Line TOC Analyzer for pharmaceutical water quality monitoring