Mechanical Testing Solutions For Rubber And Plastics

Importance Of Mechanical Testing In Rubber And Plastics

-

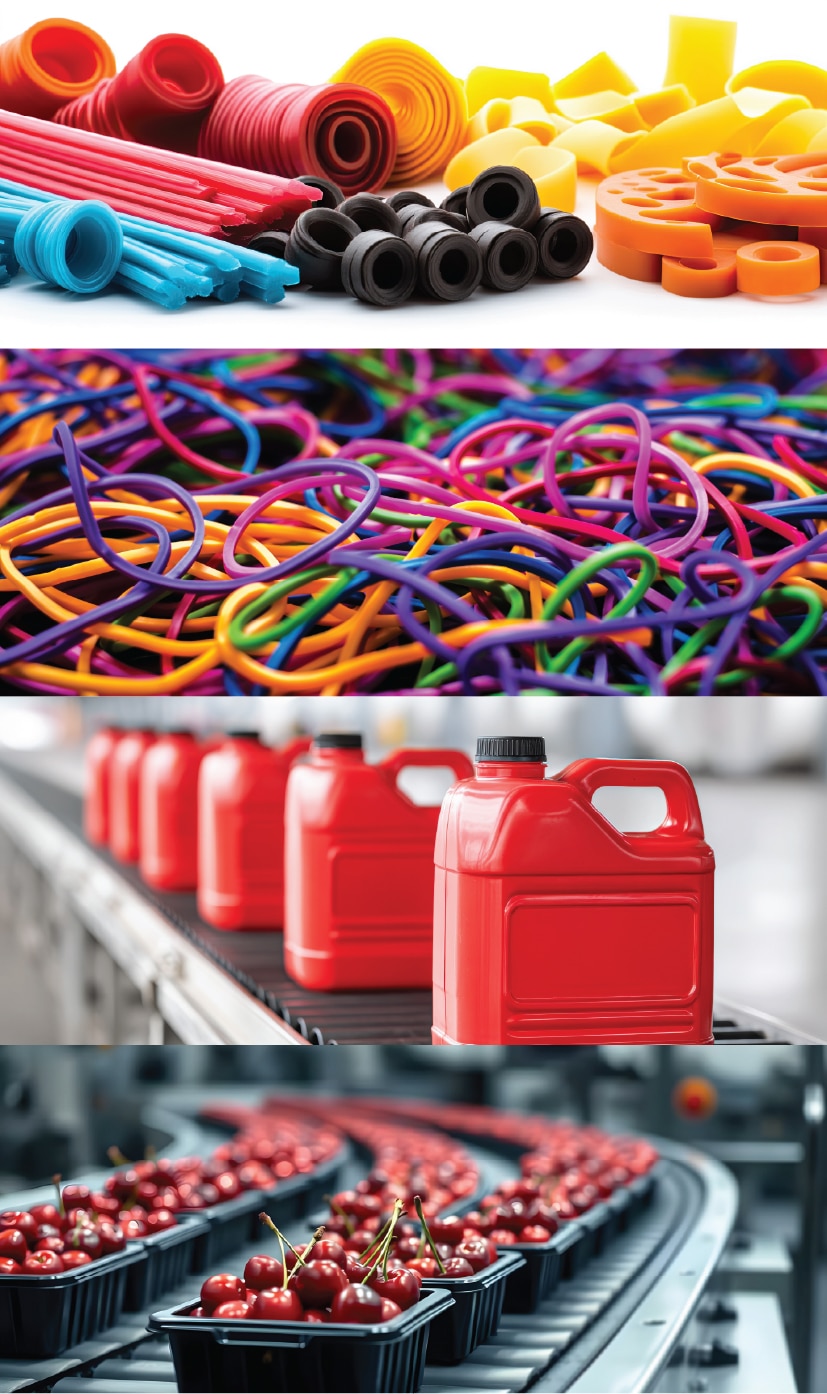

Accurate mechanical testing is essential to guarantee the performance, safety, and durability of plastics and rubbers in demanding applications. These materials play a critical role in industries where their mechanical properties—such as tensile strength, elongation, and modulus—directly influence product reliability and compliance with industry standards.

Shimadzu’s Universal Testing Machines (UTMs) are engineered to meet the unique challenges of testing plastics and rubbers. With advanced features like high-precision extensometers, specialized grips, temperature chambers, and automated workflows, Shimadzu UTMs provide unmatched accuracy and repeatability. Whether you’re testing the tensile strength of a plastic film, the elongation of an elastomer, or the compressive properties of a rubber gasket, Shimadzu systems deliver reliable data to support product development, quality control, and regulatory compliance.

Moreover, these UTMs are compatible with a wide range of international testing standards, including ASTM D638, ISO 527-1, ISO 37, and ASTM D412, ensuring that your results meet international standards. Additionally, the integration of advanced software simplifies data analysis, enabling manufacturers and researchers to make informed decisions with confidence.

-

Advanced Mechanical Testing Solutions

Interested In Shimadzu’s UTM? Fill in the form below!

-

Accurate mechanical testing is essential to guarantee the performance, safety, and durability of plastics and rubbers in demanding applications. These materials play a critical role in industries where their mechanical properties—such as tensile strength, elongation, and modulus—directly influence product reliability and compliance with industry standards.

Shimadzu’s Universal Testing Machines (UTMs) are engineered to meet the unique challenges of testing plastics and rubbers. With advanced features like high-precision extensometers, specialized grips, temperature chambers, and automated workflows, Shimadzu UTMs provide unmatched accuracy and repeatability. Whether you’re testing the tensile strength of a plastic film, the elongation of an elastomer, or the compressive properties of a rubber gasket, Shimadzu systems deliver reliable data to support product development, quality control, and regulatory compliance.

Moreover, these UTMs are compatible with a wide range of international testing standards, including ASTM D638, ISO 527-1, ISO 37, and ASTM D412, ensuring that your results meet international standards. Additionally, the integration of advanced software simplifies data analysis, enabling manufacturers and researchers to make informed decisions with confidence.

Types Of Testing

| Test Type | What It Measures | Typical Plastic/Rubber Application | International Standards (Examples) |

|---|---|---|---|

| Tensile Test | Material's strength and ability to stretch without breaking | Rubber bands, seals, plastic films | ASTM D638, ASTM D412, ISO 527, ISO 37, ISO 6383-1, ISO 34, JIS K6911, JIS K6902, JIS K7161, JIS K7162 |

| Compression Test | Ability to resist crushing or squashing under load | Foam cushions, rubber buffers, plastic supports | ASTM D695, ISO 604, ASTM D575, ISO 7743, JIS K7181, JIS K7220 |

| Bending (Flexural) Test | Resistance to bending forces and flexibility before breaking or permanent deformation | Plastic panels, flexible rubber strips | ASTM D790, ISO 178, ISO 1209-1, JIS K6902, JIS K7221, JIS K7171, JIS K7074 |

| Dynamic Mechanical Test | Response to repeated or oscillating forces, showing elasticity and damping behaviour, fatigue, and failure evaluation | Vibration dampers, shoe soles, automotive parts, machining components | ISO 6721, ASTM D 5023, ASTM D 5024, ASTM D 5026 |

| High-Speed Tensile And Compression Test | Mechanical behaviour of materials under high-speed loading conditions | Materials used in applications like automotive crash safety, aerospace engineering and defense, where materials must endure intense and sudden forces | ISO 18872 |

| Flow Characteristics Test (Rheology & Viscosity) | How the material flows when heated or melted, affecting its processability in manufacturing | Injection molded parts, rubber, and plastics (thermoplastic & thermoset) composites | JIS K 6300-1, ISO 289-1,2,3,4, ASTM D 1646 |

Shimadzu Solutions - Tailored To Your Needs

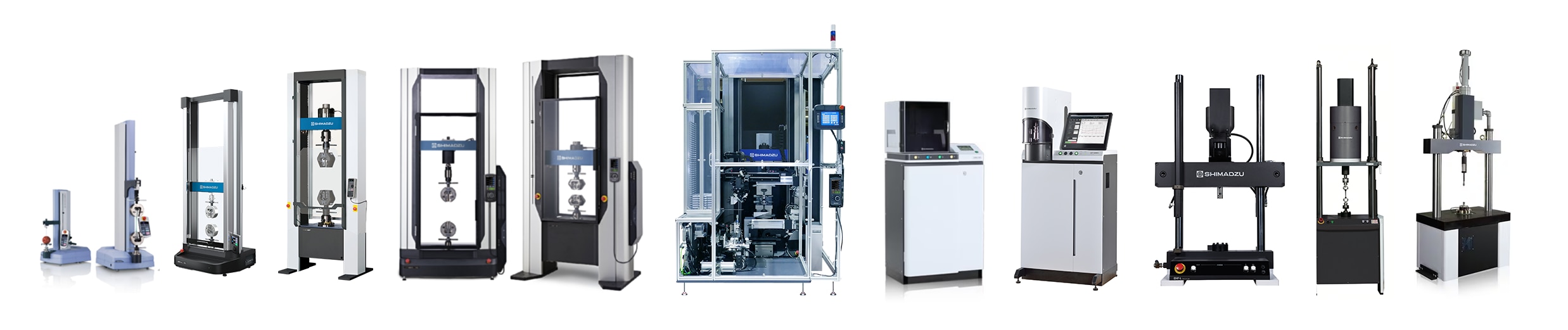

EZ-X Universal Testing Machine (1N up to 5kN)

The Shimadzu EZ-X is a compact, single-column tabletop Universal/Tensile TesterMachine designed for smaller load and sample sizes. It is particularly suited for texture analysis in food applications, measuring properties such as chewiness, crispiness, cohesiveness, brittleness, mastication, gumminess, springiness, and more.

AGS-V (up to 10kN) And AGS-X2 Universal Testing Machine (20kN to 300kN)

The Shimadzu Autograph AGS-V and AGS-X2 Series provide the best cost-to-performance and practical testing solutions for a wide array of applications. Offering high-level control and intuitive operation, the AGS-V and AGS-X2 series set a new standard for strength evaluations while providing the utmost in safety considerations in a modern, stylish design.

AGX-V2 Universal Testing Machine (1N up to 600kN)

The Shimadzu AGX-V2 is a flagship dual-column Universal/Tensile Tester Machine, featuring the latest advancements in testing technology. Available in both tabletop and floor models to accommodate varying load capacities and sample sizes, it is suitable for testing a wide range of materials, including glass, textiles, ceramics, plastics, rubbers, plastometers, elastomers, composites, metals, alloys, and more.

Electromagnetic Force Fatigue And Endurance Testing System EMT

High-speed repeated load tests can be performed at a maximum velocity of 2 m/s and a maximum stroke of ±50 mm,utilizing clean and quiet electromagnetic force as the driving power—eliminating the need for oil. The spacious test area also allows for environmental testing with the optional constant temperature tank.

Servopulser Table-Top Fatigue and Endurance Testing Machine EHF-L Series

Fatigue and impact testing assess the durability of raw materials or components by evaluating their fatigue strength and impact properties under various environmental conditions. These compact tabletop models, featuring a top-mounted actuator on an L-type loading frame, are versatile tools capable of performing a wide range of fatigue and endurance tests. They are suitable for testing materials like polymers and rubber, as well as small components or parts.

High-Speed Tensile/Impact Testing Machine HITS-X

As the demand for safety and reliability grows, evaluating the dynamic strength (impact properties) of materials andcomponents has become increasingly critical. This machine provides essential data, including maximum test force,energy, and displacement, at speeds of up to 72 km/h (20 m/s). It is available in two configurations: a tensile load type(HITS-TX) and a punching type (HITS-PX).

Capillary Rheometer Flowtester CFT-EX

This device evaluates viscosity properties by analyzing their relationship to temperature, pressure, and flow velocity forflowable materials. It is highly useful in research and development, production processes, and quality control across a wide range of materials, including thermoplastic resins, thermosetting resins, toners, composite materials, ceramics, and rubbers.

Mooney Viscometer SMV-301/301RT

The SMV-301 / 301RT enables users to measure Mooney viscosity, scorch time, minimum Mooney viscosity, and otherrubber properties in compliance with JIS, ISO, and ASTM test standards. Featuring excellent temperature recovery and user-friendly operation, it is also suitable for stress relaxation measurements and tests requiring variable rotor speeds.

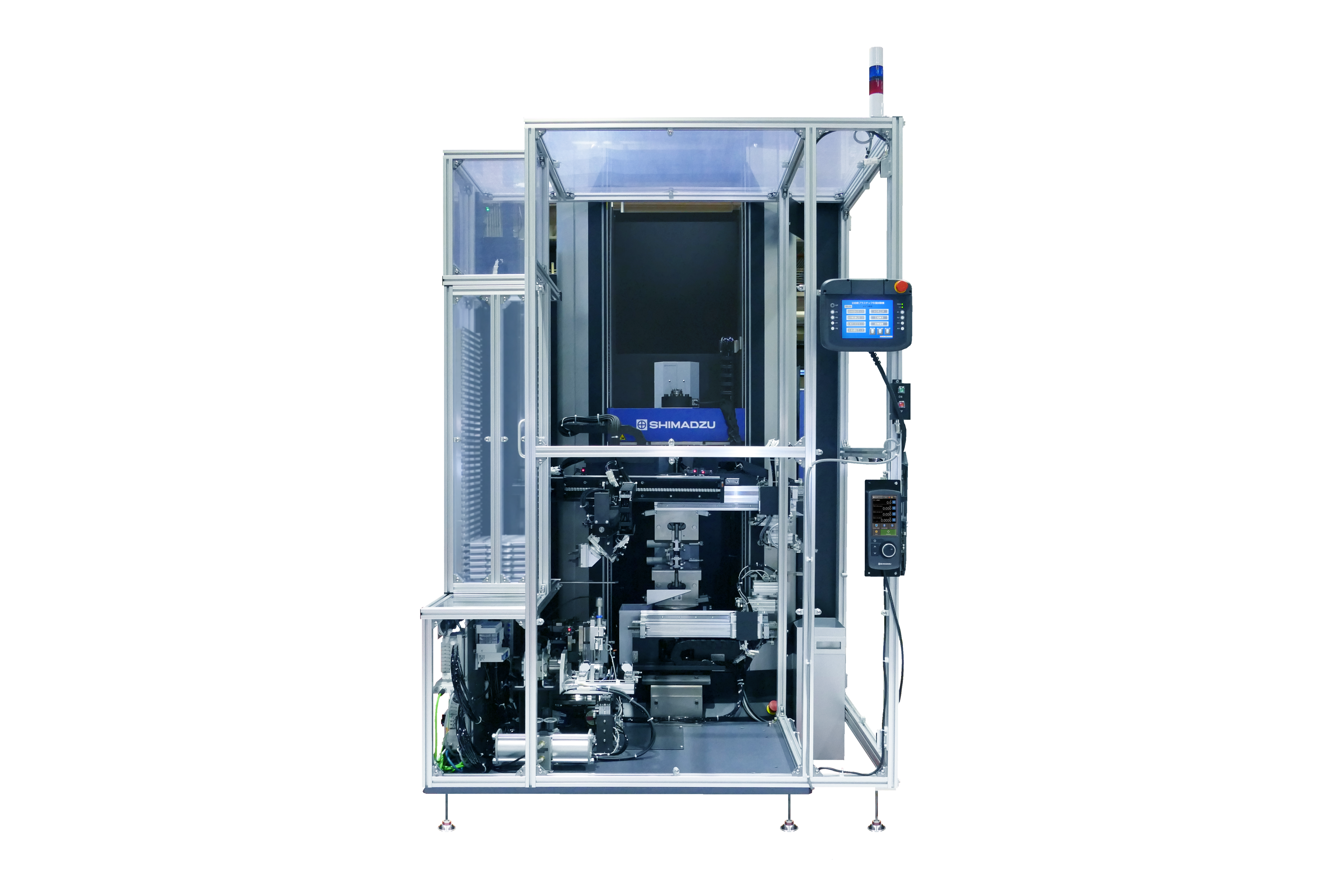

Fully Automatic Testing System (Plastics and Rubber)

With Shimadzu’s latest fully automatic testing system, plastic and rubber mechanical properties evaluation can be simplified easily. The robotic transfer arm can expertly handle test specimens on its own, accurately performing tensile and bending tests in compliance with ISO/JIS. Capable of delivering up to 240 tests consecutively with high accuracy, the system delivers fast, consistent, and reliable results right from the first time.

Application Solutions eBooks

Instruments For Evaluations Rubber And Plastics

Rubber and plastic products are used in a wide variety of areas. Evaluations of their basic performance and the components that determine their performance are indispensable for product development and quality control. Shimadzu not only offers a wide array of evaluation instruments, it also provides comprehensive support from application to after-sales service.

Recycled Plastic Analysis Solutions

Recycling plastics presents a promising solution for reducing waste and conserving our planet’s natural resources, yet it comes with its own set of challenges, including contamination.

In our latest eBook, discover how Shimadzu is tackling these challenges head-on with cutting-edge strategies. Our multifaceted evaluation assesses the quality of recycled plastics, ensuring they are safe and effective for various applications.

Emerging Trends In The Plastics And Rubber Industry

The plastics and rubber industry is evolving rapidly, driven by sustainability, technology, and customer demands.

Key Trends Include:

Recycled Plastics

Innovations in recycling ensure high-performance applications for automotive, packaging, and consumer goods, aligning with sustainability goals.

Automation

Fully automated plastic and rubber testing machines enhance efficiency, reduce errors, and enable faster, more reliable testing processes through AI and smart manufacturing technologies.

Sustainable Packaging

Biodegradable materials and lightweight solutions are replacing single-use plastics, balancing cost and environmental responsibility.

Reinforced Plastics

Lightweight composites with glass or carbon fibers are gaining traction in automotive, aerospace, and construction for improved performance and efficiency.

Increased Demand For Testing In Extreme Conditions

Materials are now tested under extreme heat, cold, humidity, and mechanical stress to meet the rigorous demands of industries like aerospace and automotive. This drives the need for advanced universal testing machines and specialized thermostatic chambers.

.png)

%20(3).png)