Achieve Robot-Based Quality in Testing of Plastics

In the plastics industry, ensuring the quality and reliability of materials is a paramount concern. From everyday packaging to intricate medical devices, the versatility of plastics underscores the need for rigorous quality testing, a critical step in meeting stringent industry standards and regulatory requirements. In this fast-evolving landscape, Shimadzu brought forth the automated testing of plastics to achieve robot-based quality testing for fast and reliable results 24/7.

This blog post delves into the transformative impact of robotic precision on plastics testing, exploring how automation is reshaping the landscape of material evaluation.

As we navigate the features and applications of these advanced solutions, we uncover how they are setting new benchmarks in the pursuit of unparalleled accuracy and efficiency in plastics testing.

Download a copy of Shimadzu’s Fully Automated Testing System for Plastics or read on for more information.

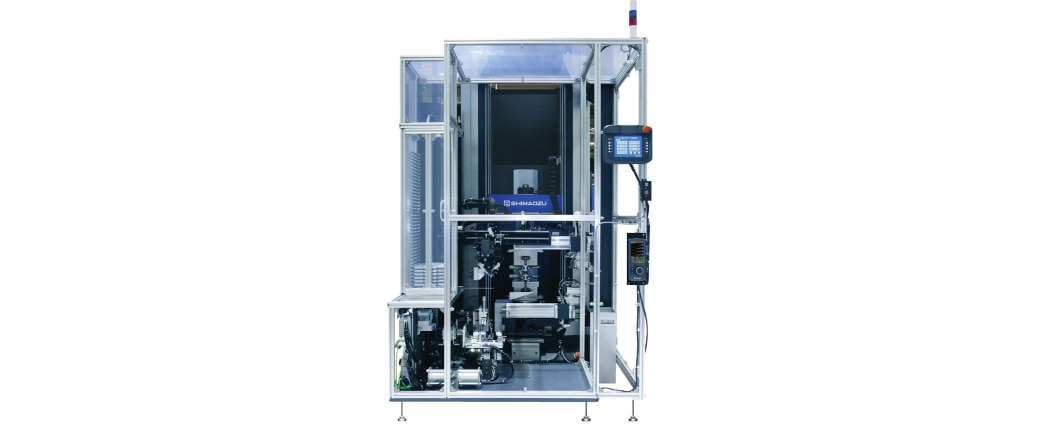

Meet Your New Partner in Lab: Shimadzu’s Fully Automated Testing System For Plastics

With Shimadzu’s latest automated system, plastic evaluation has never been easier. The robotic transfer arm can expertly handle test specimens on its own, accurately performing both tensile and bending tests in compliance with ISO/JIS. Capable of delivering up to 240 tests consecutively with high accuracy, the system delivers fast, consistent, and reliable results right from the first time.

Wide Range of Applicable Materials

Materials that can be tested include semi-rigid or rigid plastic, thermoplastics, thermosets, elastomer, rubber, etc.

Setting New Standards in Plastic Evaluation

- Standard compliance: ISO 527, JIS K7162, ISO 178, JIS K7171

- 24/7 Operation with increased testing capacity and throughput

- Eliminates manual repetitive workflows

- Long-term costs savings

- Improved result accuracy, reproducibility and reliability

- Clear accountability and easy compliance

- Improved operation safety

Unique Features

Its unique features include its ability to enable consistent placement and measurement enable high repeatability and reliability. It can also accommodate a wide range of specimen sizes to meet diverse application needs, together with its automatic specimen dimension measurement where single-point, three-points, and nine-points selections are available.

With its fully automated capabilities, the system sets the benchmarks in plastic evaluation by enabling consistent placement and measurement for optimal repeatability, while also accommodating a wide range of specimen sizes.

Discover More about Shimadzu’s Fully Automated Testing System for Plastics

AGX-V2 Series: The Highest Class Of Testing Machine In The Industry

AGX-V2 is the world’s first series of testing machines equipped with a voice operation device. The series consists of five models, including a standard model; one equipped with a large color LCD touch panel for heightened testing efficiency; a model with a wide testing space for testing large parts; and a separately installed controller model, which is useful for new materials development.

At its core, the AGX-V2 is distinguished by its high rigidity frame; multiprocessors, high-speed sampling and high-accuracy automatic control; an intelligent crosshead; stroke limit switches; a high degree of safety; a controller equipped with a progressive user interface; and software that supports the creation of test conditions and data processing with intuitive operability.

The AGX-V2 also includes a range of safety features, including a protective safety cover, overload detection, and a self-check function. This commitment to safety also extends to the user experience with a smart controller featuring a progressive user interface, enhancing operability and ensuring a seamless testing process.

The legacy of Shimadzu in testing machines is embedded in the AGX-V2, representing over a century of manufacturing excellence. As the culmination of the continuous evolution of the AUTOGRAPH, Shimadzu's renowned line of testing machines, the AGX-V2 embodies a commitment to staying at the forefront of technological advancements. This commitment is further fueled by insights gathered from customers worldwide, ensuring that the AGX-V2 meets the diverse and evolving needs of industries across the globe.

Download our brochure to discover more about AGX-V2’s capabilities.

Beyond our newly released system and AGX-V2 product, Shimadzu offers comprehensive solutions for plastic material evaluation, including the evaluation of plastic materials, evaluation of raw materials, product evaluation, and product evaluation.

In this 54-page compendium book, learn about quality control, particle size analysis, molecular weight distributions, analysis of additives and impurities, as well as structural analysis for plastic evaluation.

Download the eBook here to Access the Solution Guide

Thank you for reading! If you are interested in our updates, stay connected with us via our Newsletters, Digital Classrooms, LinkedIn, Facebook, or Youtube.